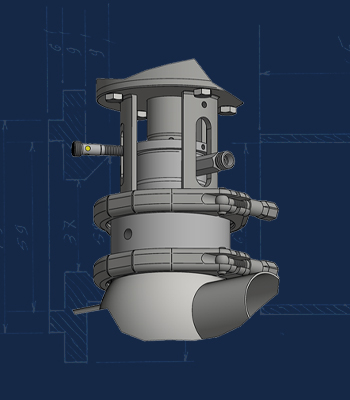

DOUBLE SEAT VALVES B925 SERIES

Reduce plant costs and increase space efficiency

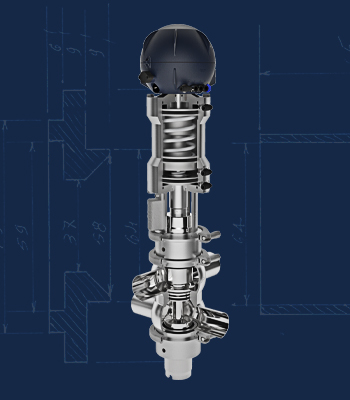

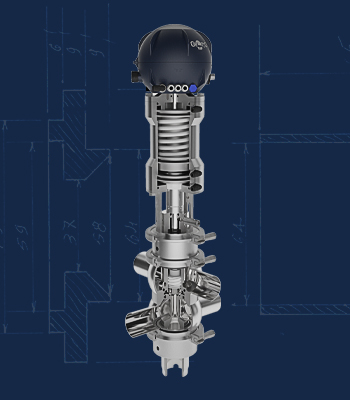

Bardiani double seat valves are designed to enable the simultaneous flow of two different products or fluids through the same valve without risk of cross contamination. They are extremely safe and their special design allow easy maintenance without use of special tools.

Extremely effective in production plants these valves allow a reduction in the number of single seat valves required and consequently optimize the use of available installation space.

They are ideal to reduce plant cost and to increase space efficiency of beverage, dairy, food, chemical and

pharmaceutical industries .

Unique features for unique and reliable valves

guarantee high hygiene and efficient maintenance.

OTHER VERSIONS

B925B DOUBLE SEAT VALVE WITH AUXILIARY EXTERNAL CLEANING

In automated double seat valves, especially where separate seat lifts are not available, an auxiliary external cleaning system will enable CIP fluids to clean the telescopic shutters and the valve stem. The cleaning operation can be performed either with the valve closed or opened. This device makes the valve very clean and hygienic.

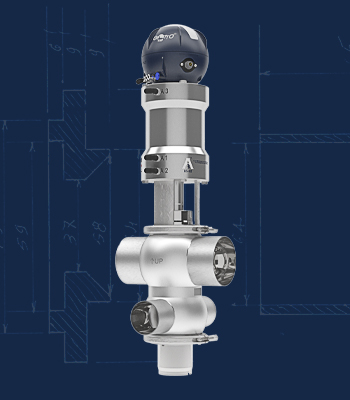

B925V DOUBLE SEAT VALVE WITH STEAM BARRIER

A steam barrier is recommended for very hygiene applications such as sterile, aseptic processing or high temperature sterilization. The steam barrier, placed between the valve body and the pneumatic actuator and placed on the lower shutter, allows safe separation between the product and the external

atmosphere.

B925A DOUBLE SEAT VALVE WITH STEAM BARRIER AND AUXILIARY

Combining an External CIP Port with a steam barrier, makes the B925 ranges of double seat valves totally aseptic and perfectly cleanable. The auxiliary cleaning system allows cleaning of the telescopic shutters and stems of the valves, while the steam barrier, placed between the valve body and the pneumatic actuator and on the lower shutter, avoids the mixing of the product and the external atmosphere.

ADDITIONAL FEATURES

AUXILIAR PROXIMITY

The auxiliar proximity is fitted between the valve body and the actuator and guarantees the complete check of the upper shutter during the cleaning operation or in case there is a water hammer in the plant that could open the upper shutter.

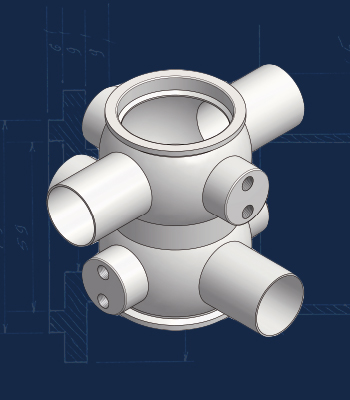

MIXED BODY SIZES

Customer can choose different body sizes to meet its production needs.

JACKET BODY

A heated body jacket is typically used to avoid the solidification of melted products. Hot water circulating in the jacket helps to maintain the temperature and product fluidity.It also helps to extend gasket life. Typically used on fats and waxes.

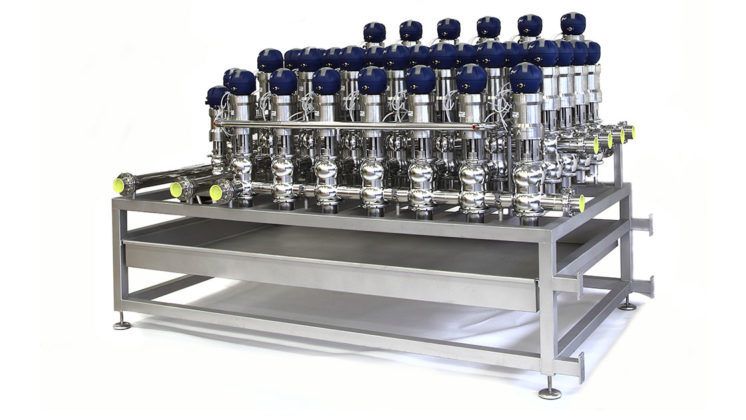

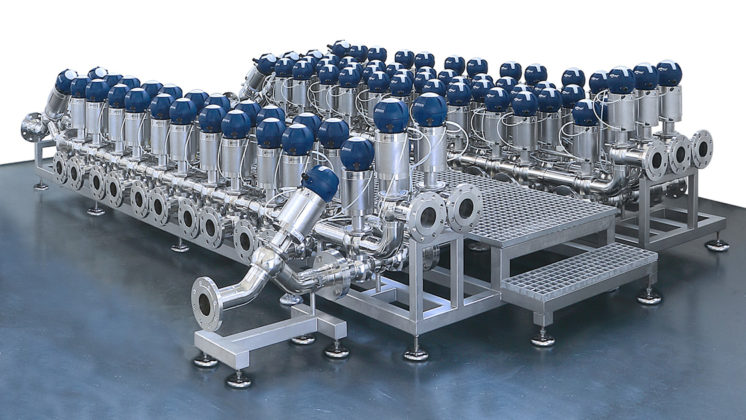

MIXPROOF VALVES CLUSTER: CUSTOMIZED SOLUTIONS

From the collaboration between the customer and Bardiani Valvole technicians, valve clusters take shape. Bardiani clusters are made according to the customer’s specific design, orbital welded, passivated and tested.

Thanks to the excellent product quality and the maximum responsiveness to the customer’s needs, the valve clusters are one of the strong points of the Bardiani Valvole production range.

THESE COMPANIES HAVE CHOSEN BARDIANI

BARDIANI VALVOLE

Bardiani Valvole is a dynamic, healthy and growing company led by Emanuela and Luca Bardiani.

Bardiani Valvole designs, produces and markets valves for health hygiene applications.

All valves are “Made in Italy” from the design stage, to the raw materials and production and come complete with personal, reliable and precise customer service.

“Thanks to our passion, high level of specialization and the seriousness of our collaborators’ work, we offer top quality valves accompanied by a flexible and reliable service with constant attention to our customers and their needs.

We make integrity and seriousness the cornerstones of our actions and relations.

Bardiani Valvole means: Quality, Passion, Seriousness and Precision”.